Food companies across Europe have had to grapple with a range of widespread economic challenges and supply chain problems in the past few years impacting the ways they operate.

Driving sales, while protecting margins and brand reputations has become much harder. Improving efficiencies, productivity and reducing food waste has become critical to this. Despite difficulties, these conditions have helped retailers to progress their sustainability strategies, with more focus placed on selecting packaging solutions that enhance environmental performance.

Stephanie Poole, Senior Business Development & Retail Manager at Sealed Air explains how the business is supporting retailers to further improve sustainability. The development of the company’s recycle-ready packaging solutions provides greater opportunity to increase the recyclability of food packaging used throughout Europe, while maintaining appealing and engaging on-pack designs. It is also a development that is helping Sealed Air to meet its own sustainability pledge of producing 100% recyclable packaging by 2025.

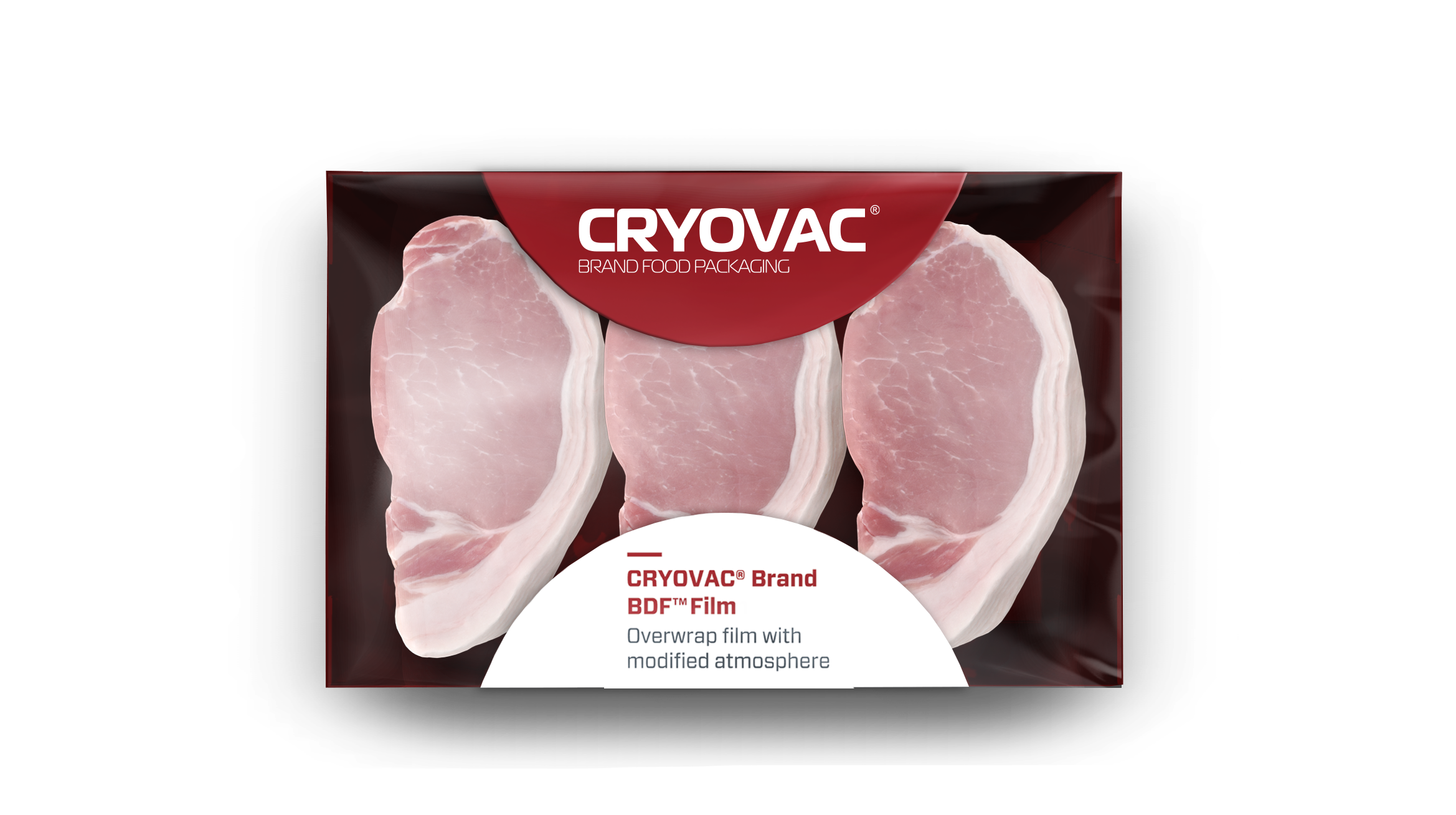

CRYOVAC® Brand recycle-ready* BDF products have been developed and tested according to protocols published by Plastic Recyclers Europe (PRE), which are aligned with those of the Association of Plastics Recyclers (APR). They both classify the films as compatible (or recycle-ready*) with LDPE4 recycling stream.

The films offer versatility to retailers and producers because they are compatible with mono-material, cardboard, compostable and reusable trays. They can be used with different-sized trays or without trays at all, on HFFS lines. The films also offer an ultra-thin protective barrier of 20 microns. This can deliver 90% reduction in material usage, compared to thick laminates or thermoforming materials** (based on tests carried out in Sealed Air laboratories. All facilities and systems are different, so results may vary).

With the development of recycling infrastructures varying across the continent, Sealed Air’s CRYOVAC® Brand range of recycle-ready* barrier display films (BDF) aim to optimise recycling compatibility across this diverse spectrum. This can help food processors, retailers and brands to improve resourcefulness and contribute towards the development of a shared circular economy.

Delivering choice and extending shelf life for retailers and consumers

Flexibility of choice is precisely what Sealed Air aims to provide with the CRYOVAC®Brand range of recycle-ready* barrier display films (BDF). The range includes BDF20M, which is compatible with LDPE recycling streams, and rBDF20M, which contains 30% certified circular resin from mass balance approach and is compatible with LDPE recycling streams. Both solutions deliver food-grade, soft plastic packaging with an EVOH barrier.

The durability of the films delivers sustainability benefits by extending product shelf life, contributing to lower levels of food waste vs. commonly used in retail PVC stretch. The film material has also been developed without any animal derivate substances, so it is compatible with vegan-compliant alternative proteins. It is also ideal for packaging fresh meat, fish, ready meals and cheese products.

Supporting compliance requirements across the continent

Recycling strategies are advancing throughout Europe, and it means that there are many complex layers of compliance for retailers and their supply chain partners to navigate.

Choosing packaging that improves compliance can help businesses to protect profitability. Environmental performance can be communicated on the packaging which makes the final product appealing to consumers who are increasingly interested in the sustainable benefits the brand offers.