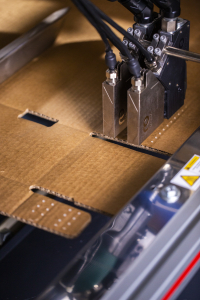

Turkish machine builder, DMS Osman Çubuk Makine Ltd. Şti, developed a new tray former with the support of Robatech and achieved a 25 % increase in production and 50 % adhesive savings compared to the standard variant.

In 2018, DMS faced a bigger challenge. “Customers demanded an increase in tray production rate and wanted to save adhesive at the same time,” Erhan Çubuk from DMS describes in retrospect. Higher production speed and the change from bead to adhesive-saving dot application (stitching) required the use of an electromagnetic application head with long service life. “SpeedStar Compact with 500 million operating cycles was the ideal solution,” says Hakan Tanriöven, Sales Manager Robatech Turkey. “Despite stitching, the trays are glued reliably. Two lines of adhesive with very small dots can be applied to the cardboard box at the same time per application head.”